Foreword: The 3806/160 rolling element and the outer ring of the four-row tapered roller bearing on the operation side of the middle roll of a six-high cold rolling mill in a factory suffered from fatigue, spalling and damage in a short time, and the bearing was burned and locked. The use and assembly of the bearing It brought a lot of inconvenience and caused great economic losses.

In response to this problem, after the technical staff of the bearing manufacturer passed the inspection of various indicators of the bearing, they tracked the bearing assembly site of the factory from time to time under the premise of excluding the bearing itself, and participated in the installation, disassembly, and maintenance work on site.

Tracking found the following series of related problems:

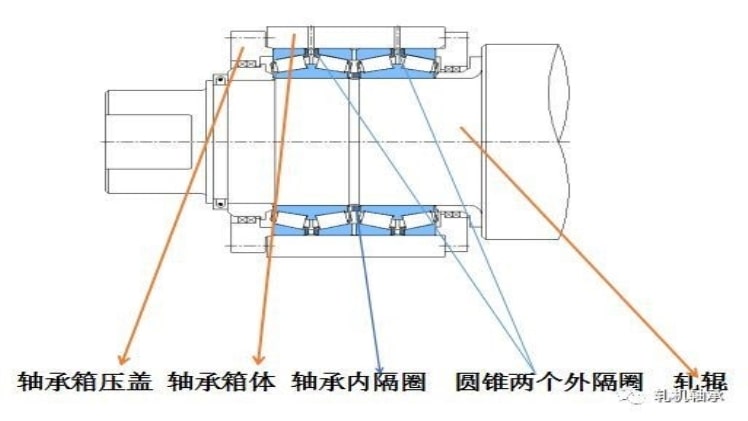

1. Structure and Characteristics of Four Row Tapered Roller Bearings

The 380000 type bearing has a compact structure, and its basic performance is basically the same as that of a double-row tapered roller bearing. It can withstand combined radial and bidirectional axial loads.

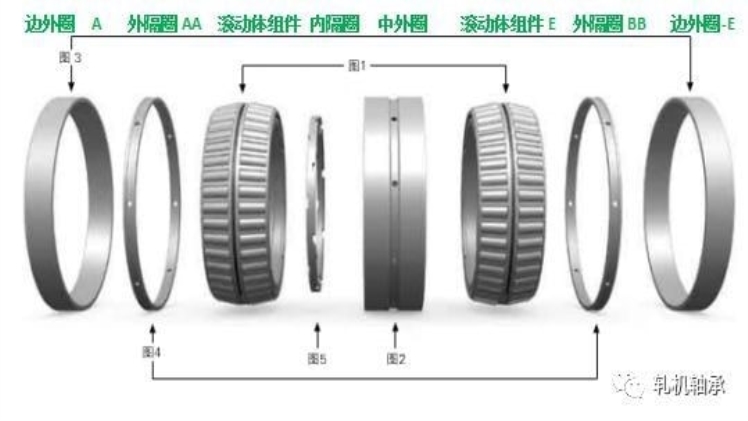

The basic structure consists of two double-row inner ring components (rolling elements, cage, inner ring ) and one double outer ring and two single outer rings, two side spacers and one inner spacer.

Character symbols are printed on the outer ring, inner ring and inner and outer spacer rings when leaving the factory, and must be installed in the bearing housing in the order of the characters and symbols during installation. Can not be interchanged arbitrarily to prevent the change of bearing clearance.

2. Four-row tapered roller bearing roller system assembly structure

3. Four-row tapered roller bearing assembly method

- The four-row tapered bearing is a separable bearing, which consists of an outer ring, a spacer, and a rolling element assembly (rolling element plus a cage and an inner ring). During assembly, the outer ring-A and the rolling element assembly-A are installed in sequence.

Outer spacer AA, middle and outer ring, inner spacer, rolling element assembly-E, outer spacer BB and the last outer ring-E are all installed in the bearing box, and then the bearing box is pressed on the gland to this point

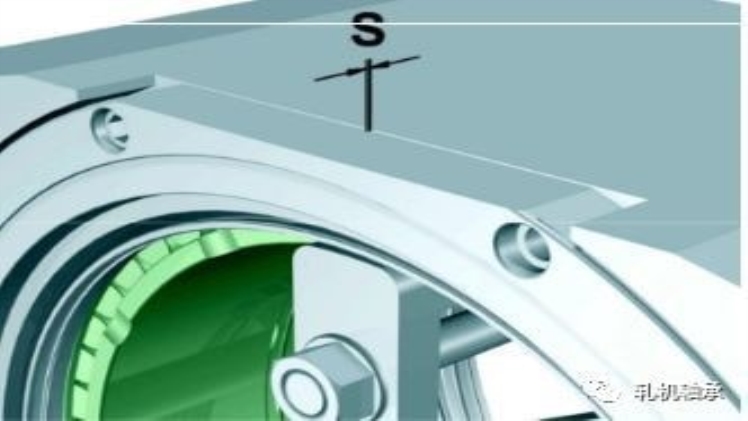

The installation of the bearing into the bearing housing is completed. In the whole assembly, in addition to the installation order, the final gland step is the core step. It is necessary to ensure that the end face of the gland and the end face of the bearing outer ring are effectively pressed against each other, that is, it cannot be given too much.

To prevent the deformation of the outer spacer ring of the bearing caused by the preload force and cause the bearing installation to change, and there should not be too much axial clearance, it is necessary to ensure that the end face of the gland is matched with the end face of the bearing.

Usually, the end face of the end cover extends After the mouth touches the bearing section, it is necessary to measure the value of the gap S between the gland and the end face of the bearing case (plug gauge), and then install an adjustment gasket of appropriate thickness to ensure the cooperation between the gland and the bearing end face, and the thickness of the gasket (rigid) H=(S+0.05).

However, the four-row tapered roller bearing assembly has a high C value, and the deviation is large, generally exceeding 0.5mm, that is, every assembly must be measured to ensure the matching of the gland and the bearing end face.

- After the bearing is assembled to the bearing box, then hoisted (the inner ring of the bearing and the roller diameter are matched with each other), and the bearing is directly set on the roller diameter. Finally, the entire bearing is accurately locked on the roller through the axial locking ring, thus forming the bearing. Combined assembly of box, roll and bearing.

4, Damage forms of four-row tapered roller bearings

After the bearing is locked and burned, the third and second columns are often damaged, and the cage and outer ring are also damaged.

5. Phenomenon Analysis of Four Row Tapered Roller Bearings

Combining the bearing characteristics, installation process and damage phenomenon, it can be analyzed that the bearing is subjected to axial forces in two directions during rolling. When the axial force is transmitted from one side, the axial force of the bearing is 1/2. 3 rows bear axial force in one direction, 2/4 row bears axial force in one direction, and 2/3 rows of bearings are easily damaged from the pictures and damage laws, which means that when the bearing is running, when the shaft When the force is transmitted, it is not the two rows of rolling elements that bear the axial force in a certain direction at the same time, but the abnormal single-row force, which causes the axial load of the bearing to drop by 50%, which will inevitably lead to abnormal burning of the bearing.

Further analysis of the cause of the single-row force can be analyzed from the bearing structure. Only after the assembly error or high wear of the spacer in the bearing will cause the axial force transmission to be blocked, which will cause the single-row rolling element to be stressed.

Therefore, the inspection The inner spacer of the bearing was damaged, and it was found that the spacer was severely worn. So far, it is concluded that the abnormal damage of the bearing is due to the shortening of the wear of the spacer in the system, which leads to the blocking of the axial force transmission and causes the bearing damage caused by the single-row force.

The wear of the inner spacer is mostly caused by the uncompressed outer ring and the gland, the gap is too large and the lubrication effect is poor.

6. Rectification measures for four-row tapered roller bearings

- Improve the hardness of the inner spacer of the bearing.

- Strengthen the lubrication measures at the spacer.

- To improve the assembly accuracy, be sure to assemble once and measure once.