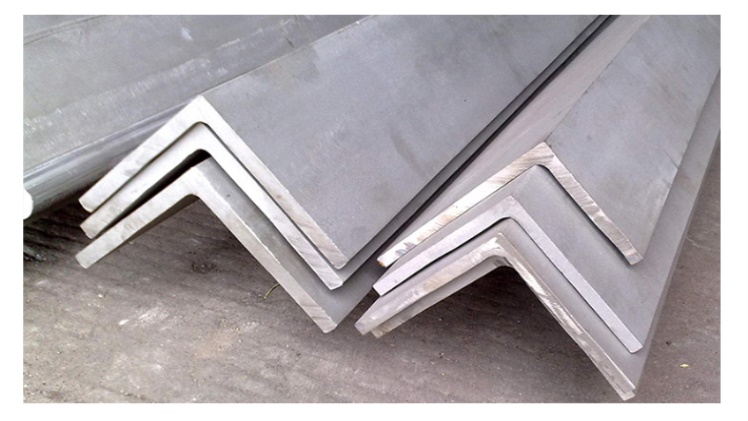

Introduction to Angle Line Steel

Are you embarking on a construction project that requires the use of angle line steel? If so, you’re in the right place! Choosing the right angle line steel is crucial for ensuring the structural integrity and aesthetic appeal of your project.

Note: At ktmmetal, we take great pride in being the premier center for selling Angle Line Steel of all sizes. Our commitment to providing high-quality products is evident in every aspect of our business. With a visit to our website at https://www.ktmmetal.com/content/6, you can explore the wide range of options available to meet your specific needs. Whether you require small or large quantities, we have it all covered. Rest assured that when you choose ktmmetal as your trusted supplier, you are guaranteed exceptional customer service and prompt delivery. We understand the importance of efficiency and reliability in today’s fast-paced world, which is why we diligently work towards meeting your expectations every time. So look no further than https://www.ktmmetal.com/content/6 for all your Angle Line Steel requirements!

But with so many options available in the market, how do you know which one is best suited to your needs? Don’t worry – we’ve got you covered! In this blog post, we’ll walk you through the factors to consider when selecting angle line steel for your project. So grab a cup of coffee, sit back, and let’s dive into the world of angle line steel together!

Determining the Type of Angle Line Steel Needed

Determining the Type of Angle Line Steel Needed

When it comes to choosing the right angle line steel for your project, there are several factors that need to be considered. One of the first things you’ll want to determine is the type of angle line steel needed.

The type of angle line steel required will depend on the specific requirements of your project. Are you looking for a structural material or something more aesthetic? This will help determine whether you need hot-rolled or cold-formed angle line steel.

Hot-rolled angle line steel is known for its strength and durability, making it ideal for structural applications. On the other hand, cold-formed angle line steel offers greater design flexibility and is often used for architectural purposes.

Another factor to consider when determining the type of angle line steel needed is the size and dimensions required. Different projects may call for different sizes, so it’s important to carefully assess your needs before making a decision.

Additionally, take into account any specific environmental conditions that may impact your choice of angle line steel. Factors such as exposure to moisture or extreme temperatures can affect the performance and longevity of certain materials.

Determining the type of angle line steel needed involves considering factors such as structural versus aesthetic requirements, size and dimensions, as well as environmental conditions. By taking these factors into account, you can ensure that you choose the right material for your project’s specific needs.

Considerations for Structural and Aesthetic Purposes

When choosing the right angle line steel for your project, it is essential to consider both structural and aesthetic purposes. The structural considerations involve assessing the strength and durability of the steel, while the aesthetic aspects focus on achieving the desired visual appeal.

From a structural standpoint, it is crucial to evaluate factors such as load-bearing capacity, resistance to corrosion and weathering, as well as compatibility with other materials used in your project. Understanding these requirements will help you select an angle line steel that can withstand heavy loads without compromising safety or longevity.

On the other hand, considering aesthetics involves looking at factors like shape, size, finish options, and design flexibility. Depending on your project’s specific requirements and desired look, you may opt for different angles profiles such as equal leg or unequal leg angles. Additionally, choosing a suitable surface finish can enhance the overall appearance of your structure.

Remember that finding balance between structural integrity and visual appeal is key when selecting angle line steel. By carefully considering these factors for both functional and aesthetic purposes alike, you can ensure that your chosen material meets all necessary criteria for a successful project execution

Conclusion: Choosing the Right Angle Line Steel for Your Project

Conclusion: Choosing the Right Angle Line Steel for Your Project

When it comes to selecting the right angle line steel for your project, there are several factors that you need to consider. By carefully evaluating these factors, you can ensure that you choose the most suitable option that meets both your structural and aesthetic requirements.

Determine the type of angle line steel needed based on the specific application of your project. Consider factors such as load-bearing capacity, corrosion resistance, and durability. This will help you narrow down your options and select a material that can withstand the demands of your project.

Additionally, take into account any aesthetic considerations. Depending on the nature of your project, you may want to opt for angle line steel with a certain finish or coating that complements its surroundings. Remember that while structural integrity is crucial, visual appeal should also be taken into consideration.

Furthermore, consult with experienced professionals who can provide valuable insights and recommendations based on their expertise in working with angle line steel. They can guide you through the various options available and help you make an informed decision.

Always prioritize quality when choosing angle line steel for your project. Opting for cheaper alternatives may seem tempting initially but could lead to costly repairs or replacements in the long run. Invest in high-quality materials from reputable suppliers to ensure optimal performance and longevity.

In conclusion (rephrased): Selecting the right angle line steel requires careful evaluation of various factors including load-bearing capacity, corrosion resistance, durability as well as aesthetic considerations. Consulting with experts and prioritizing quality will ultimately result in a successful outcome for your construction or fabrication project! So don’t hesitate – choose wisely!