Whether it be the everyday machinery you use for your daily tasks or the machines you find in industries, it is necessary to take care of them regularly. If one is regular when it comes to machine maintenance, it can increase their life spans. By making them last for a longer period, it will end up costing you less. Having to buy machines after every few years is much more costly than spending a little from time to time or their maintenance. This is even more important for large-scale machinery used in industries. Similarly, medical injection molding companies have to be conscious about the same problem since medical machinery can be very costly too.

Here you can go to learn more about the tutflix

This means there are many hurdles and problems that machinery creates for businesses. Fortunately, there is one solution that can help solve most of these issues. Machine maintenance is the key to efficient and effective work for your business. Before getting into how to improve machine maintenance, we need to know what it is first.

What Is Machine Maintenance And Why Is It Important?

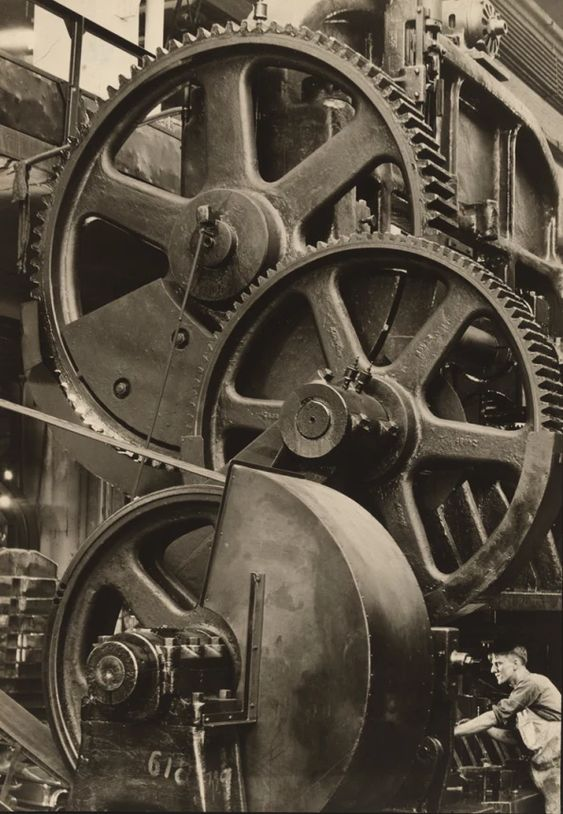

Machine maintenance is the process through which one ensures that it continues to work effortlessly. The upkeep required for the maintenance can be done through different methods. Some of these methods can include lubricating gears, cleaning surfaces, and performing regular checkups. Regular checkups can often consist of routines performed on machines after a certain interval of time to make sure everything works smoothly. An example can be a control valve manufacturer regularly having to ensure that its customers are cleaning their valves at least once a year.

It is important to develop a strategy to make sure all your equipment is working throughout the year. Machine maintenance does not only have a direct impact on the machines but also on the people using them. Performing machine maintenance can make it easier for people to use the equipment. It can also minimize the risks of any last-minute emergencies that might be caused by equipment failure.

Visit Here : newsfilter

How To Improve Your Machine Maintenance

Now that we know what exactly machine maintenance is, effectively utilizing it is left. Below are several ways you can use and improve your machine maintenance.

Visit now isaimini best website

Data Collection

To make a plan or strategy for something, it is important to fully understand it first. The same applies when forming a strategy for your machine maintenance. To come up with a strategy specifically tailored for your machines, one needs to collect data first.

This accurate data will help you in devising a precise plan for your machines. The data can be anything such as how quickly do jar packing machines get dirty or when do your machines start squeaking. This data will help you create a timeline in your mind as to how often do you need to perform maintenance.

Scheduled Maintenance

Now that you have collected enough data about your equipment, it is time to form a plan. Maintenance is the most effective when done regularly. Hence it is important to form a maintenance plan for your equipment that can be followed regularly. This includes regular checkups. However, the scheduled time for each machine may differ from the other. The time that it takes one machine to start getting slow and rusty might be different from the time it takes another.

Regular maintenance checks will also help you catch any problems early on. This will help in avoiding any last-minute failures. Identifying the problem as soon as possible is just as important as its maintenance and aim trainer.

A Well-Equipped Plan

Just having a maintenance plan is often not enough, being able to perform it properly is just as important. Performing the scheduled maintenance plans with accurate precision, focus, and attention to detail is not an easy task to do. This is why the ones performing it must receive training. This is so the workers can obtain skills to perform maintenance tasks effortlessly. The plan in itself must also be accessible to the workers while easy to maintain and follow. The tools and liquids used for the maintenance should be of high quality and free of contamination.

Safety

The people or workers carrying out the plan are just as important as the plan itself. And so, their safety must be ensured while performing machine maintenance. They must be trained correctly and know of the protective measures needed to be taken while carrying out their tasks. The equipment provided to them must also be safe.

Conclusion

At the end of the day, it isn’t that hard to ensure that your machines continue to work smoothly. With just a well-formulated plan and extra effort, you can avoid having to regularly buy new equipment. Frequently performing machine maintenance can create a better work environment for not only your machines but also your employees.

Play safe all kind of games 메이저놀이터