Scaffold tower construction is an ideal “mobile” adaptation for vertical works at big heights. The main purpose of the towers is to safely carry out work on building cladding, restoration of architectural objects, repair work, cleaning, replacement of ventilation and lighting elements, as well as the construction of houses and any other objects. The design is also convenient because it can be easily and quickly disassembled, it is possible to increase or decrease the height, install it on slight differences in the floor. But, in addition to all the advantages, there are also limitations—the height of the structure should not exceed more than 21 meters, because it becomes extremely unstable, especially if placed outdoors.

In this article I will talk about how the tour tower is arranged, how and where it is better to use it. You will receive detailed information on what technical parameters you need to consider when choosing a mobile construction tower or a stationary one. Also, do not forget about the material of manufacture—which of them is considered the most practical and most profitable.

The tour construction tower is a convenient and practical device for the reason that it moves to the right place without problems, without requiring assembly and disassembly. Lightweight, compact. It is not surprising that the scope of its use is not only the construction of houses, but also other types of work.

Possible areas for application:

- Construction and repair (painting, whitewashing, painting);

- Installation of various structures and communications at height;

- Cleaning and cleaning of vertical areas (washing of windows, facades);

- Installation of visual advertising;

- And also at any other kind of events.

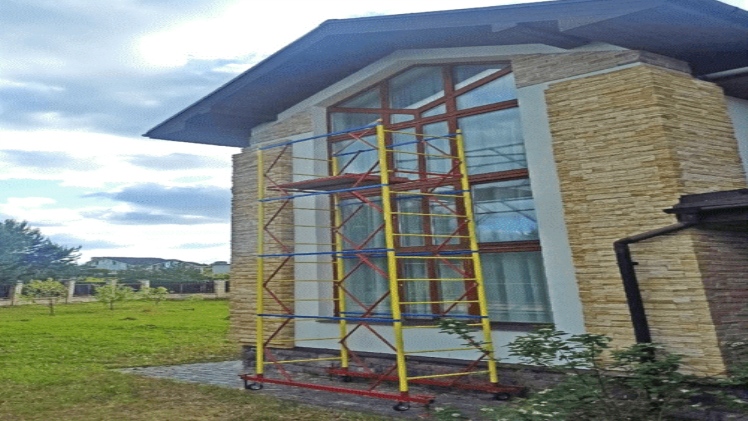

Design features of mobile towers

The mobile tour tower is equipped with massive, strong swivel wheels of small diameter, which will allow you to freely move it in any plane and install exactly in the position that is necessary for comfortable work. In order for her not to go anywhere, there is a foot brake on each wheel. This is good because you do not need to bend down, come up with different ways to fix the wheels with improvised items. But for additional stability, manufacturers provide for the installation of jacks that level it on any plane and 100% prevent it from moving.

All structural elements of the tower are fixed to each other by diagonal crossbars. They create additional rigidity of the structure and do not allow it to fall apart.

But there are still small tricks—if the height of the tower exceeds the mark of 7 meters, it is necessary to purchase stabilizers for it. These accessories are not always supplied with towers, but, in fact, they can always be bought for almost any model. And if we consider the option of aluminum towers, then there they can be found in almost every configuration.

Experienced builders often also use telescopic tower tours. They are presented in the form of retractable structures, used when you need to climb to a height of more than 2.1 meters. This type of construction towers allows you to rise to a height of more than seven meters. The design has convenient wheels with which you can easily transport the tower from one place to another. Due to the fact that the support structure has anti-slip protection, this type is the safest and most reliable, but at the same time the most expensive.

What influences the material of manufacture

The material from which the structure is made is a guarantee of its reliability and durability. It is an important criterion when choosing tower tours. There are several options on the Ukrainian market today, from which a tour tower can be made. The most popular are steel and aluminum. At the same time, they are worthy competitors. Despite the fact that they have a fairly large difference in the weight of the structure itself, the load on the tower is about the same—on average, 200 kg of additional weight.

The most durable is the steel structure, it is strong, heavy, and therefore extremely stable. The main plus is its affordable price, and as you know, this material can withstand any load, thanks to which steel models are leaders in sales and are characterized by the greatest popularity. All steel towers are coated with anti-corrosion paint, which allows for a long time to work in all weather conditions.

The aluminum tower of the tour is the lightest. In terms of strength, modern die-cast aluminum is not inferior to steel. In addition, it does not rust or corrode due to the epoxy coating. And the biggest plus is that the specific gravity is several times lighter. That is, aluminum scaffolding will always be easier to move around the site, disassemble and assemble, and this is especially convenient when you are doing work indoors.

Aluminum towers are very often used for facade and interior work, although such a tower is more expensive than steel. So when choosing, look at what your budget allows: steel or aluminum.

Construction tower assembly

Mobile construction tower, used in the process of construction and installation works with

erection, reconstruction, and repair of buildings and structures installation of lighting equipment and ventilation for the placement of workers and materials

directly in the production area.

The Tura tower is a spatial tower-type structure of flat stairs 1.2 m high with three rungs.

Install on a flat, rammed platform parallel to each other, two bases with locks inward.

The lower sections are installed on two bases, which are interconnected by a volumetric diagonal. Volumetric diagonal is installed on every fourth tier. Parallel ladders are installed in the base cups and form a section.

To ensure the rigidity of the structure itself, the sections are interconnected by ties (beams), which are attached to the locks of the stairs and dumbbells.

The structure is assembled to the required height. If work is required at a height of more than 5 meters, to ensure stability, the tower must be equipped with stabilizers that are fastened with clamps to the main structure of the tower. Railing ladders and railing dumbbells are installed on the last tier, this section comes with the base and is usually painted red.

The tower must be installed strictly vertically using Stainless Steel Screws supports. The slope of the surface must be compensated for by leveling the tower with supports. For ascent and descent, it is necessary to use only the ladders provided in the kit; movements on the outer part of the structure are not allowed.

The bases have four screw supports and four wheels. The wheels are used to move the tower. Screw bearings compensate for irregularities in the supporting surface. The working platform is equipped with working decks (platforms) and work area fencing rails.

For ascent and descent, it is necessary to use only the ladders provided. In this case, movements on the outer part of the structure are not allowed.